Overland Tech and Travel

Advice from the world's

most experienced overlanders

tests, reviews, opinion, and more

Pinnacle products: A white paper

“There are dinner jackets, and dinner jackets. This . . . is the latter.”

If you recognized the line—and, more important, if you smiled and nodded approval—then I don’t need to introduce you to the concept of a pinnacle product. But on the slim chance you aren’t a Bond movie fan, let’s talk.

It’s axiomatic that the overwhelming majority of consumer products have to be compromises.

This is because, above all, a product has to sell to be successful, to earn a profit for its maker. Thus function, performance, weight, ergonomics, style, durability, reliability, sustainability, fair labor practices—a hundred parameters—might each be considered and incorporated to lesser or greater degrees depending on how much it costs to include each one—or perhaps rather how much profit it takes away. And generally a product that includes all of them simply costs too much to produce and offer at a price most consumers will (or can) pay.

But for a scant few products, a scant few manufacturers through the years have chosen to throw this paradigm out the window. Those manufacturers ignored their accountants and made the product the best they could possibly make it—and figured out afterwards how much they needed to charge for it to make a profit.

Sometimes this bold approach works; other times it does not. Consider, for example, the 1992 McLaren F1—still considered by most automotive experts to be the finest supercar ever produced. The designer, Gordon Murray, overlooked not a single detail to make the F1 the best it could be. Components as seemingly unimportant as the throttle pedal had days and days of design input and were made from the finest and lightest materials available—then remade again and again until they were perfect. The exhaust heat shield was gold foil, because gold reflects heat better than any other metal. The proof of the F1’s brilliance came when a barely modified example won the 24 Hours of Le Mans outright. Twenty eight years later the F1’s 242 mile-per-hour top speed has not been topped by another naturally aspirated vehicle.

And yet. McLaren planned a production run of 300 F1s—but only 106 were ever made. It was ahead of its time, and it was exceptionally expensive: $800,000. By comparison a 1990 Porsche 959—a pinnacle machine of its own—ran about $300,000 (although it’s thought Porsche lost at least $200,000 on each one it sold).

So producing a pinnacle product is clearly a risk, even if it is considerably less expensive than that F1.

A pinnacle product does not have to be the best at everything; it simply needs to be the best at what the manufacturer wanted it to be. The early decades of Rolls-Royce motor cars exemplify this. The first Silver Ghosts weren’t intended to be high-performance or even particularly luxurious. They were built to be supremely reliable and durable, and they were, winning numerous reliability trials, and leading an outside source—The Autocar —to proclaim the Rolls-Royce “The world’s best motorcar,” a slogan the company quickly adopted. In fact the early Rolls-Royces were reliable and durable enough that they went to war, serving with T.E. Lawrence in the Middle East and modified with armor for other campaigns.

A pinnacle product can be a classic—that Silver Ghost, or the Wehrmacht jerry can, for example—but a classic product isn’t necessarily pinnacle. The original Land Rover essentially defines classic in the world of expedition vehicles, but it was built within numerous cost-cutting parameters, chiefly due to the rationing of steel and the extreme economic difficulties faced by the Rover company and England in the late 1940s. The box-section chassis, for example, was an elegant solution to the need to reduce the amount of steel in each vehicle while retaining adequate torsional rigidity, but the material was necessarily thin and thus very prone to rust issues, and for reasons of cost was never galvanized—a compromise that endured through the end of production in 2015.

A pinnacle product can be eclipsed in performance by a later product that doesn’t qualify as pinnacle, simply because technology advances to the level where even less-than-pinnacle technology is better than what came before. It’s undeniable that a modern DSLR camera produces higher-quality images than could be produced by a 35mm 1954 Leica M3. But the M3 (another example of a product both pinnacle and classic) was made with single-minded attention to craftsmanship and durable function. Today’s cameras, however well-built they may be, are constructed with the secure knowledge that they will be outdated within five years. No modern DSLR will be held in the same regard 60 years from now as the Leica is.

Pinnacle products do not necessarily have to be expensive items, although in virtually all cases they are among the most expensive products of their type. I’d consider Snow Peak’s double-wall titanium coffee mug an example of a “budget” pinnacle product, and at $50 it’s attainable—but a perfectly serviceable stainless substitute can be had for a fifth the price.

I’ve decided to start a new, occasional entry on Overland Tech and Travel, nominating and telling the story of a product I view as pinnacle. Most will have at least something to do with overland travel, but not necessarily—some might just be interesting.

These stories won’t be simply slavish homages to absurdly expensive consumer products. Many times the technology or materials that are introduced or proven in pinnacle products subsequently trickle down to more affordable products. Thus it’s worth investigating the former even if you think the idea of spending $50 on a coffee mug—or $800,000 on a car—is insane.

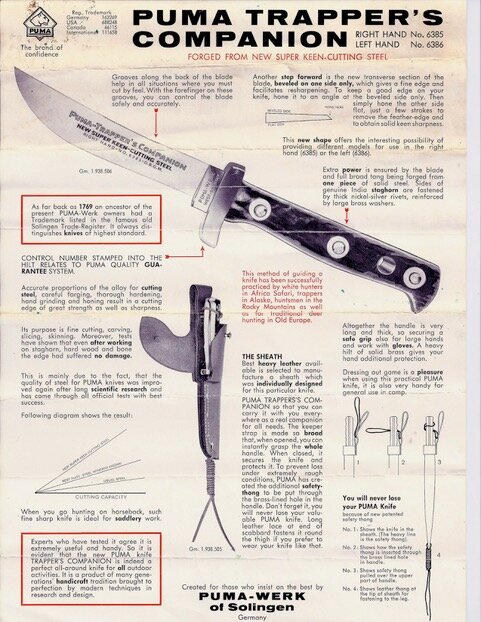

Also, I believe any pinnacle product should above all serve a purpose and be used for that purpose. Consider, for example, the knife pictured above. It was my introduction to the concept of (and, okay, obsession with) pinnacle products.

As a teenager itching to spend yard-work money on my first real knife, I pored over the usual Field and Stream ads for Buck, Schrade, and Western—but with my first look at an ad from Puma, I knew there was something different about them. Even in black-and-white the superior fit and finish was obvious. They were forged in West Germany, individually serial-numbered. The scales were Sambar stag, not plastic or jigged bone. Every Puma knife displayed a tiny indent on the blade where the steel’s correct hardness was confirmed with a diamond point. (You can see it here just off the corner of the “P” in Puma.)

Even among the various beautiful Puma models there was one that jumped out at me. It was called the Trapper’s Companion—the very name whispered of wilderness adventures. It had the most beautiful lines I had ever seen on a knife: The blade showed the even, perfect sweep of a saber, or the sheer of a sailboat. The blade was bevelled on one side only—something I’ve not seen since in a knife—and thus could be ordered in right or left-hand configuration. For a left-handed kid this made it all the more entrancing.

Even the sheath was special—a full-length, protective leather cover with an embossed puma head, and a leather thong that threaded through a hole in the knife’s handle to secure it against loss.

Puma produced a full-page information sheet for the Trapper’s Companion, including exhaustive descriptions of each feature—which I memorized down to the last detail.

Image courtesy pumaknifeman.com

There was just one problem. The Trapper’s Companion cost an astronomical $32—at the time when a Buck Personal was $14.

So, bowing to teenage economic reality (and impatience—my best friends already had good knives), I bought the Buck. And it was a fine knife. And meanwhile, my pinnacle knife, the Trapper’s Companion, did not sell well at its premium price, and was soon dropped from the importer’s catalog.

But I never forgot about it. I never threw away the ads I had cut out. And decades later, I found a Trapper’s Companion in fine condition on eBay, and paid somewhere around, er, ten times its original price for it. You could easily imagine I then put it on a shelf to admire, but I’ve field-dressed deer and elk with it. I wish I could travel back in time to visit that teenaged me and show him.

I’ve been accused more than once of being a snob, or elitist, or at the very least too attached to the idea of having stuff. I maintain my philosophy is almost exactly the opposite. That early penury drove home to me the real value of high-quality equipment that lasted longer and was thus actually cheaper in the long run than products that cost less to begin with. In 1983 I bought a Marmot Grouse sleeping bag that was insanely expensive at the time—a true pinnacle product sheathed in cutting-edge Gore-Tex and stuffed with the best goose down available. Thirty seven years later that bag is still in perfect condition and has lost at most a half inch of loft. Who knows how many fiberfill bags I would have used up and given away over the same period? My SVEA 123 backpacking stove is ten years older than that; I think it’s earned its steep $12 price several times over.

So there’s my introduction to and explanation of the new series, along with my first pinnacle product. Much to come. If you have any suggestions I’d be happy to consider them.

Even if it’s a dinner jacket.

(Postscript—tragically, the Puma company changed hands twice in the 1980s and 1990s, some production was moved out of Germany, and quality overall plunged. The pinnacle era of the Puma Knife Company was over. Older Pumas now command a substantial premium. See some really fine ones here.)

The ARB BASE roof rack

A couple of weeks ago I got a media release from ARB—an invitation to a video presentation introducing “one of the most significant products in ARB’s history.”

I was suitably intrigued. It’s no secret that I find ARB’s products to be consistently among the very best on the market, and several of them—the Twin air compressor, the ARB diff lock, the Intensity driving lamps, Old Man Emu suspension—have no peers. In fact, the only recent ARB product that underwhelmed me was their Pureview 800 flashlight, a serviceable but mediocre effort.

So what could “one of the most significant product’s in ARB’s history” be?

I considered. Hmm . . . what about a winch? That seemed to be a notable hole in the inventory. Given that the two best winches on the market right now—the Warn 8274 and the Superwinch Husky—are each decades old, an opportunity seemed to present itself.

Others: an overland-capable trailer? Several Facebook friends suggested products for the upcoming Ford Bronco. Hmm . . .

So I tuned in at the specified time, typed in my super-secret media password, and heard that what I would be learning about was ARB’s new . . . BASE roof rack (for Build, Attach, Set, Explore).

Wait. Seriously, I thought? A roof rack? That’s it? But I settled in to watch.

And, the more I watched, the straighter I sat in my chair and the closer attention I paid.

No, I wouldn’t call a new roof rack earthshaking, even from ARB. However, I do think the company has advanced roof-rack design by a significant leap over the competition. Here’s why.

The basis of the rack is a fully welded aluminum structure, available in six sizes, from 45 by 50 inches up to 50 by 84. Each member is of hollow, boxed construction, with an additional internal reinforcing strut running its entire length—lending great strength with minimal weight. The rack’s crossbeams are oriented transversely, which reduces each beam’s length compared to longitudinal beams, further increasing rigidity. (Transverse beams also offer better support for carrying long items.) The only potential downside is increased wind noise, and ARB claims their tests indicate that most noise is generated at the front beam, for which they have introduced a wind deflector. The only bolts in the rack are on the corner pieces, which can be removed to run wiring internally.

The really clever innovation is the dovetail extrusion running along the side of each beam, to which all the tie-down brackets and accessories mount. Since the dovetails sit below the level of the rack floor, they do not interfere with cargo. Unlike T-slots, they will not pack up with dirt and debris, yet placement and arrangement of tie-down points and accessories is virtually unlimited, and the full strength and stiffness of each beam runs through the dovetail. (If you already have a bunch of T-slot accesories, adapters are available.)

The dovetails make it easy to equip the rack with a perimeter rail in whatever configuration you like: full, quarter, three-quarter, and “trade,” the latter of which only runs along the sides to facilitate loading ladders, lumber, etc., and would be the way to go if you carry an Oz Tent.

The dedicated premium mount for a Hi-Lift jack is brilliant. The mounts rotate out to form a cradle for the jack, making it easy for one person to load or unload. Well done.

Eyebolt attachments for the dovetails facilitate the use of standard ratchet straps; ARB also offers custom ratchet straps with dovetail-compatible ends.

A recovery track base allows fitment of brand-specific attachments for MaxTrax and other recovery boards. And of course there are specific mounts for a range of other accessories—not all of which I recommend carrying on a roof rack at the same time.

I’m not a fan of roof-rack mounted driving lamps; nor am I a fan of light bars; however, ARB has designed a very stylish light bar that integrates beautifully with the front of the rack. You might not have even noticed it in the photo above.

Of course a full range of mounting brackets will be available in addition to a rain-gutter option.

I think roof racks should be used and loaded with discretion, for reasons of weight and CG in addition to windage issues. However, if you need one, first impressions are that the ARB BASE rack should be at the top of your list. I hope to lay my hands on one soon and give it a full workout.

Why I don't (hardly ever) buy from Harbor Freight

Everyone knows it’s unsafe and stupid to work under a vehicle that is not firmly supported by jack stands. Well, it turns out it can be unsafe and stupid to work under a vehicle that is supported by jack stands—if you bought them at Harbor Freight.

Recently the company announced a recall of some of its jack stands due to “. . . the possibility they could fail under load.” Customers who returned their stands were given a refund or credit. Apparently many of those customers, being, shall we say, somewhat slow learners, used the credit to buy the jack stands with which HF replaced the defective units.

Wrong move. Harbor Freight just announced a recall of those jack stands, too. Reportedly these stands fail due to the use of old and worn-out casting equipment that produced shafts with insufficient tooth engagement.

I understand the need to economize. But there are right ways to do so, and wrong ways. I actually own a Harbor Freight product: a two-ton hydraulic press. I bought it because I needed one for a particular job and wanted my own, but I knew I wouldn’t use it more than every few years. I also knew that if it broke, no dire consequences would ensue. The structure is a simple steel framework, the ram an ordinary hydraulic bottle jack, easily replaceable. It wasn’t a tool that could injure (or kill) me if it failed, nor could it strand me in the middle of nowhere.

The Harbor Freight story is an object lesson in the economics of cheap Chinese goods. Sure, labor costs are lower in China, but don’t imagine for a second that’s the only way companies that manufacture there cut costs. I took apart a Chinese winch a few years ago, a winch that appeared to be an exact copy of a Warn XD9000 from the outside despite costing a third as much. Once you got beyond the exterior, however, the differences were stark.

Obviously not all products made in China are junk—or cheap. I’m typing this on a pricey Macbook Pro that proclaims in zero point type on the back, “Designed by Apple in California. Assembled in China.”

If you’re going to go for a cut-price Chinese product, however, just make sure it’s not one that could turn you into a garage pizza.

ARB product launch

This is intriguing. ARB is usually pretty low-key with new product launches, but they’re making a bit of a splash with this one. Details after the embargo on July 21.

Designing a Vehicle Build, Including a Virtual Troopy Tour – Free online workshop

Have you ever daydreamed about designing, and then actually building, your “dream vehicle” for overland adventure? In this free Overland Tech and Travel workshop, we walk you through how we started keeping field notes on their “perfect overland vehicle” in the 1990s, and then by 2016 began the process of buying, designing, and building our ultimate overlanding vehicle, a 1993 Land Cruiser Troop Carrier converted to a pop-top camper in Australia and eventually—after 29,000 kilometers and four years exploring Australia and southern Africa—imported home to Arizona.

RESOURCES FROM THE WORKSHOP:

Download PDF of build and specs. (left)

Download PDF of additional specs, resources. (this information also copied below)

Download vehicle weight / distribution report.

IMPORTATION – The U.S. allows virtually any vehicle over 25 years old to be imported without the need to conform to current standards. That means Troopies powered by the 1HZ engine—introduced in 1990—are now eligible.

AUStoUSA.com Darwin Troopy: $16,000 U.S. 1993, eligible for importation in 2018. [bought June 2016]. 244,800 km / 152,000 miles on odo.

Expedition Centre in Sydney. Daniel Fluckiger, Australian/Swiss owner

Mulgo aluminum pop-top conversion for the Troopy (and the Defender 110). Full standing headroom in the back, drop-down double bed with mattress; when closed raises the height of the vehicle only 30mm.

Arrived in Australia mid-July 2016 for a three-week crossing of the Simpson Desert.

FIRST ROUND OF ACCESSORIES FOR 2016 MADIGAN LINE / SIMPSON DESERT

Warn XD9000S winch in existing ARB bumper, spooled w/100 feet of 3/8-inch Dyneema.

ARB Intensity 21 round LED lamps

National Luna NL50 fridge/freezer combination

125-watt photovoltaic panel

Brackets for MaxTrax at front of roof

Second round of modifications (2017), Tasmania & RED DESERT CENTER TRIPS

Cabinetry per CAD drawings

95-liter stainless-steel water tank between chassis rails

ARB Twin air compressor

Kaymar rear bumper/carrier

Recaro Specialist M seats and SupaFit covers

Eezi-Awn Bat 270 awning, two side panels

Third round of modifications (2018) WESTERN AUSTRALIA DESERT CROSSING

Ultimate Suspension springs, twin-tube gas shocks, “Sumo” springs

180-liter Long Ranger rear fuel tank

New 16x7 wheels and BFG All-Terrain tires

INSURANCE: progressive.au. and then Assurantiekantoor Alessie (Neth.) for Africa

SHIPPERS: International Vehicle Shipping Services (IVSSUK); Trade Ocean in Namibia

COST: Total investment to date, not including the Recaro seats or repairs, is $43,000 US.

MILEAGE TO DATE: 18,000 mi / 29,000 km over 4 years, 3 continents

Will it, or won't it? The new Defender Hard Top.

Small(er) diameter steel wheels? Check. Coil springs? Check. (air springs optional on the 110). Seat delete for more cargo space? Check. Lower price? Check.

All this is fine, but as far as I’m concerned the best thing about the Defender Hard Top is that it deletes the bizarre body-color side panel for a business-like solid rear quarter. It’s the only version of the new Defender in which, if you squint just the right way, you can kinda sorta see a few styling elements from the original Defender—the flat back (“Verticality,” in LR manager Gerry McGovern-speak), the outward bulge of the body below the greenhouse. These elements are present on the standard Defender as well, but they are completely overshadowed by that illogical square of body color stuck where no body color should be.

(I’m not even going to mention the “Adventure Pack” Flintstones lunchbox option available for the same spot.)

From Land Rover’s press office, here’s the rundown on the Defender Hard Top.

Land Rover has experienced unprecedented global demand for New Defender 90 and 110 since its successful world premiere last September and the new Hard Top models will be the next additions to the legendary bloodline.

Defender’s aluminium-intensive D7x body architecture is three times stiffer than the best body-on-frame designs. Sharing its strong body structure and next-generation Electrical Vehicle Architecture (EVA 2.0) with passenger models, the Defender Hard Top is being developed by Land Rover Special Vehicle Operations to deliver unrivalled durability, practicality and toughness.

Michael van der Sande, Managing Director, Land Rover Special Vehicle Operations, said: “We will maximise the functionality and usability of New Defender’s cargo area, with tough materials and clever storage solutions to ensure it surpasses the capability of any previous Defender Hard Top.”

The 90 and 110 Hard Tops will both feature independent coil-sprung suspension, with advanced electronic air suspension also available on the 110. Both set-ups will provide outstanding off-road geometry, with ground clearance of 291mm, while the 110 Hard Top will have approach, breakover and departure angles of up to 38, 28 and 40 degrees respectively (in Off-Road height). Full technical details will be confirmed later this year.

Nick Collins, Land Rover Vehicle Line Director, said: “New Defender 90 and 110 Hard Top will be the toughest, most capable and most connected commercial 4x4s we have ever produced. They have been engineered to meet global safety standards and deliver impressive long-haul comfort, giving businesses and professionals the best of all worlds.”

An impressive payload and towing capacity of up 3,500kg* will combine to make New Defender the ultimate commercial 4x4. The flexible cabin has no second or third-row seats, but the optional front-row jump seat means it will still accommodate up to three people. Land Rover’s clever ClearSight Rear View mirror system preserves rearward visibility when the jump seat is occupied, or when the load space is full. It uses a live video feed from a rear-facing camera to give drivers an unobstructed view at all times.

New Defender Hard Top will be a world-class tow vehicle, with a raft of technologies to help hitch, drive and reverse safely while pulling a trailer. Land Rover’s intelligent Advanced Tow Assist system takes the stress out of difficult reversing manoeuvres by letting drivers steer trailers with their fingertips using a rotary controller on the centre console.

The maximum wading depth of 900mm is also supported by a new Wade programme in the Terrain Response 2 system, which ensures drivers can ford deep water with complete confidence – so important supplies will always get through.

So far this sounds like a new Defender a real overlander could appreciate.

But will it come to the U.S.? Sadly, all indications are that it won’t. The Hard Top is aimed at commercial users, and Land Rover has hope measured in negative integers of breaking into any commercial market in the U.S. The press release for the Hard Top was not even forwarded to U.S. news sources.

In all logical probability our choices will be restricted to the more upmarket versions of the Defender. They will still be impressively capable vehicles, but more expensively equipped and mounted with larger-diameter wheels and rear seats. And that panel.

If I got one, the first thing I’d do would be to take it to a body shop and have that panel painted.

Paraphrasing Mick Jagger:

“I see that panel and I want it to turn black. No color any more I want it to turn black . . .”

Step 22 Gear's Silent Jack

I know what you’re thinking, but keep reading. This isn’t just another polyurethane handle keeper.

Some time ago I wrote about my homemade Hi-Lift jack keeper, here. It functions superbly in terms of keeping the jack handle secured, with no possibility of the keeper shifting. However, my keeper does nothing to reduce the rattling of a stowed Hi-Lift, which can be annoyingly loud if, say, you have the jack mounted on a roof rack above the driver or passenger window, as many of us do, or vertically in front of a door, as some FJ40 and Jeep owners do.

Enter the Step 22 Gear Silent Jack. The polyurethane handle keeper is more or less the same as a hundred others—although I found it fit tighter (better) than most. The trick to this keeper is the second molded piece that wedges between the base of the handle and the shaft:

This piece locks the entire jacking mechanism solid, completely eliminating movement. Remove the jack’s foot (easy with Step 22’s spring-loaded base-plate pin) and there is no noise, period.

The fit is very tight—I had to squeeze hard to get the handle keeper over the handle and shaft with the wedge in place—but that indicates to me it should stay effective for a long time. You also have an extra piece to keep track of, but that shouldn’t be a big deal. I found it t be a simple but worthwhile update to the standard poly handle keeper.

Step 22 is here. Take a look at their equipment cases too. I’m hoping to try one of their tool cases soon.

Hint: When using “Search,” if nothing comes up, reload the page, this usually works. Also, our “Comment” button is on strike thanks to Squarespace, which is proving to be difficult to use! Please email me with comments!

Overland Tech & Travel brings you in-depth overland equipment tests, reviews, news, travel tips, & stories from the best overlanding experts on the planet. Follow or subscribe (below) to keep up to date.

Have a question for Jonathan? Send him an email [click here].

SUBSCRIBE

CLICK HERE to subscribe to Jonathan’s email list; we send once or twice a month, usually Sunday morning for your weekend reading pleasure.

Overland Tech and Travel is curated by Jonathan Hanson, co-founder and former co-owner of the Overland Expo. Jonathan segued from a misspent youth almost directly into a misspent adulthood, cleverly sidestepping any chance of a normal career track or a secure retirement by becoming a freelance writer, working for Outside, National Geographic Adventure, and nearly two dozen other publications. He co-founded Overland Journal in 2007 and was its executive editor until 2011, when he left and sold his shares in the company. His travels encompass explorations on land and sea on six continents, by foot, bicycle, sea kayak, motorcycle, and four-wheel-drive vehicle. He has published a dozen books, several with his wife, Roseann Hanson, gaining several obscure non-cash awards along the way, and is the co-author of the fourth edition of Tom Sheppard's overlanding bible, the Vehicle-dependent Expedition Guide.